Vladivostok, Russian Federation

The objective of the study is to develop formulations for pastila containing seaweed, and to determine the quality indicators, safety parameters, and shelf life of such products. The research tasks included determining the chemical composition and energy value of pastila; establishing its organoleptic, microbiological, and toxicological properties; and determining the shelf life of the finished product. The production technology for pastila using seaweed is presented. Japanese kelp, one of the most widely harvested seaweeds, was added to the pastila. The inclusion of kelp, which contains alginates, water-soluble dietary fiber, fucoxanthin, and other physiologically important substances, resulted in a nutritious and health-promoting product with a pleasant and distinctive taste and aroma. The pastila formulations were developed using seaweed, vegetables, fruits, and berries. Key ingredients include Japanese kelp, carrots, pumpkin, dried apricots, and black currants. A stepwise drying regime was applied: at 46 °C for 5 hours, then 58 °C for 5 hours, and finally 35 °C for 3 hours. Studies of the finished product revealed protein content of 1.35-2.5%, lipids 0.24-0.4%, carbohydrates 50-74%, minerals 1.7-3.0%, and moisture 15.0-25%. The energy value ranged from 201.4 to 285.9 kcal. Organoleptic evaluation showed that the pastila with seaweed had a pleasant berry-fruit flavor with a mild seaweed aftertaste. The shelf life of the pastila, when packed in polymer bags and stored at 18 °C and 75-80% relative humidity, was substantiated as 6 months. Microbiological indicators, heavy metal content, pesticides, and other chemical impurities were within the limits established by current technical regulations.

technology, pastila, kelp, chemical composition, safety indicators

Introduction

A healthy and balanced diet is a key factor in supporting the normal functioning of the human body and maintaining both physical and psychological well-being. The consumption of natural foods enriched with beneficial nutrients helps preserve health, maintain productivity, and enhance the body’s resistance to infectious diseases [1-3]. However, the modern food industry produces a large number of products with high levels of fat, simple carbohydrates, salt, preservatives, and various chemical food additives. Regular consumption of such products leads to metabolic disorders, resulting in excess body weight, elevated cholesterol levels, and impaired intestinal function. Therefore, it is essential to develop food products that contain only natural nutrients and are enriched with biologically active substances and dietary fiber. A wide range of beneficial substances is found in plant-based raw materials – fruits, vegetables, and berries [4, 5]. Along with terrestrial plant materials, marine algae serve as a valuable source of physiologically important substances. Seaweed is rich in alginic acids, dietary fiber, and other beneficial compounds. Its inclusion in the human diet promotes detoxification and helps regulate the balance of beneficial intestinal microflora. For example, kelp contains a high amount of fucoxanthin, which plays an important role in regulating blood sugar levels, thereby helping to prevent the development of diabetes. The large amount of dietary fiber in kelp also helps prevent overeating, allowing one to feel full for an extended period due to the nutritional saturation of the body with essential substances [6-8]. Pastila is a confectionery product made from finely ground fruits and berries with added sugar [9, 10]. The incorporation of seaweed during its production enhances the nutritional and functional value of the final product.

Objects and methods of research

The objects of the study were samples of pastila made with seaweed. The following ingredients were used in accordance with relevant ISS standards: Frozen seaweed (ISS 31583-2012); Fresh carrots (ISS 32366-2013); Fresh pumpkin (ISS 7975-2013); Dried apricots (ISS 32896-2014); Frozen black currants (ISS R 51074-2003); Berry jam (ISS 34113-2017); Granulated sugar (ISS 33222-2015); Agar-agar (ISS 16280-2002); Sesame seeds (ISS 12095-76); Coconut flakes (ISS 51074-2003). Protein and mineral content were determined according to ISS 7636-85. Lipids were assessed by express method in accordance with ISS 28829-86. Moisture content was measured using an ML-50 moisture analyzer. Drying of pastila was carried out using a Tabai PERFECT OVEN – ORIGINAL PV-110 convection dryer. Microbiological indicators were determined in accordance with ISS ISO 7218-2015. Organoleptic evaluation was performed using a profiling method. For constructing the profile diagrams, a developed scoring scale was used, presented in Table 1.

Table 1

Scoring scale for organoleptic evaluation of seaweed pastila quality

|

Quality indicators |

Description |

Points |

|

Appearance |

Rectangular, triangular, or oval plates without chips, 1.0-1.5 mm thick |

5 |

|

Same shape, no chips, 1.6-2.0 mm thick |

4 |

|

|

Same shape, no chips, 2.5-3.0 mm thick |

3 |

|

|

Same shape, minor edge chips, 2.5-3.0 mm thick |

2 |

|

|

Same shape, surface chipping, 2.5-3.0 mm thick |

1 |

|

|

Texture |

Jelly-like, moderately firm |

5 |

|

Jelly-like, firm |

4 |

|

|

Jelly-like, very firm |

3 |

|

|

Jelly-like, very firm, hard |

2 |

|

|

Jelly-like, very firm, very hard |

1 |

|

|

Color |

Dark orange or burgundy with kelp inclusions |

5 |

|

Dark orange or dark burgundy with kelp |

4 |

|

|

Brown with kelp |

3 |

|

|

Dark brown with kelp |

2 |

|

|

Dark brown with grayish tint |

1 |

Ending of Table 1

|

Quality indicators |

Description |

Points |

|

Aroma |

Dried fruits or berries |

5 |

|

Same, with a hint of kelp |

4 |

|

|

Same, with pronounced kelp |

3 |

|

|

Faint aroma of fruits and kelp |

2 |

|

|

Weak aroma, stale odor |

1 |

|

|

Taste |

Moderately sweet, fruity or dried fruit taste |

5 |

|

Same, with slight kelp aftertaste |

4 |

|

|

Same, with pronounced kelp |

3 |

|

|

Faint aroma of fruits and kelp |

2 |

|

|

Weak aroma, stale odor |

1 |

The content of toxic elements was determined according to ISS 33824-2016, ISS 30538-97. The content of pesticides according to ISS 32689.1-2014.

Results and discussion

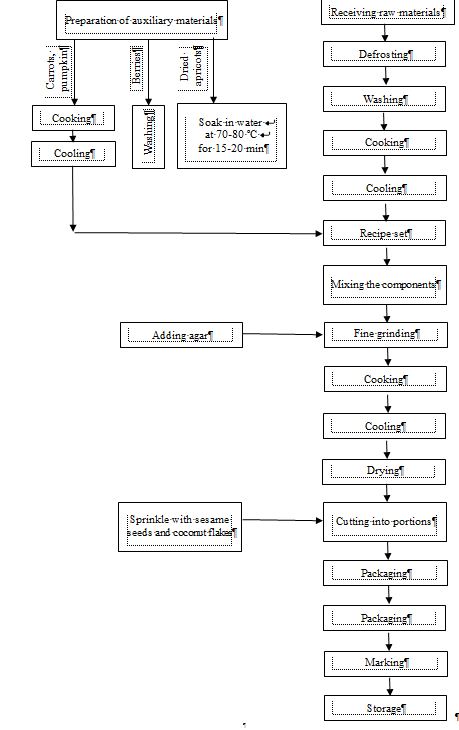

As a result of previous research, formulations of pastila with added seaweed were developed. The main components included Japanese kelp, carrots, pumpkin, currants, honeysuckle jam, dried apricots, agar-agar, and sugar. Seaweed was first thawed and thoroughly rinsed in water. Then, a 2 : 1 ratio of water to seaweed was added and heated until boiling. The water was drained, and new water acidified with citric acid was added. After boiling resumed, the kelp was cooked for an additional 15 minutes. Vegetables (carrots, pumpkin) were peeled, chopped, and boiled. After cooling, they were finely ground. Dried apricots were softened by soaking in hot water (70-80 °C) for 15-20 minutes. The prepared raw materials were mixed with sugar, agar-agar solution was added, and the mixture was cooked for 30-40 minutes. It was then cooled to

50-55 °C, spread in a 0.5 mm thick layer on trays, and dried using a stepwise regime: Phase 1-46 °C for 5 hours; Phase 2-58 °C for 5 hours; Phase 3-35 °C for 3 hours. After drying, the pastila was dusted with sesame seeds or coconut flakes, sliced into portions, and packaged. Pastila with seaweed was made according to the developed recipes (Table 2).

Table 2

Formulations of pastila with seaweed

|

Component |

Main ingredients, kg per 100 kg of finished product |

||||

|

Recipe 1 |

Recipe 2 |

Recipe 3 |

Recipe 4 |

Recipe 5 |

|

|

Seaweed (kelp) |

21.0 |

28.0 |

36.0 |

36.0 |

26.0 |

|

Carrot |

16.4 |

– |

17.0 |

14.5 |

|

|

Pumpkin |

– |

15.5 |

– |

26.0 |

|

|

Dried apricots |

13.6 |

15.4 |

16.5 |

18.0 |

|

|

Black currant |

– |

12.2 |

– |

– |

– |

|

Honeysuckle jam |

– |

13.5 |

|||

|

|

Auxiliary ingredients |

||||

|

Sugar |

21.4 |

26.0 |

30.0 |

27.0 |

– |

|

Agar-agar |

1.5 |

||||

|

Sesame seeds |

– |

0.5 |

– |

0.5 |

– |

|

Coconut flakes |

0.5 |

– |

0.5 |

– |

0.5 |

The technological scheme for the production of pastilles with seaweed is shown in Fig. 1.

Fig. 1. Technological scheme for the production of pastila with seaweed

The chemical composition and caloric content of the finished products were determined. Depending on the recipe, the pastila contained 1.31-2.3% protein, 0.29-0.48% lipids, 50.2-73.65% carbohydrates, 1.7-3.0% mine-

rals, 15.03-24.92% water. The energy value was 201.4-285.9 kcal (Table 3).

Table 3

Chemical composition and energy value of pastila with seaweed

|

Recipe |

Protein, % |

Lipids, % |

Carbohydrates, % |

Moisture, % |

Minerals, % |

Energy, kcal/100g |

|

1 |

1.55 |

0.35 |

59.80 |

21.89 |

2.3 |

232.7 |

|

2 |

1.31 |

0.41 |

67.14 |

17.03 |

2.5 |

260.5 |

|

3 |

1.35 |

0.29 |

73.85 |

15.03 |

2.7 |

285.9 |

|

4 |

1.46 |

0.33 |

64.50 |

18.50 |

3.0 |

249.0 |

|

5 |

2.30 |

0.48 |

50.20 |

24.92 |

1.7 |

201.4 |

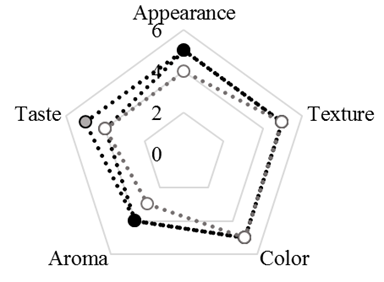

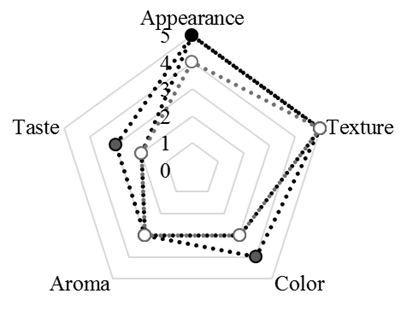

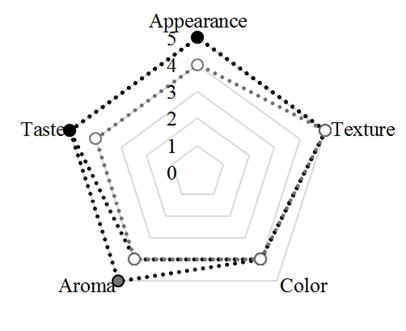

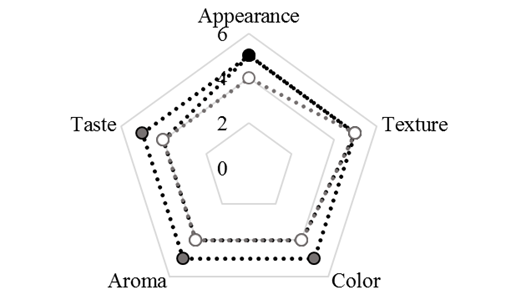

Sensory evaluation showed that the seaweed pastila had a berry-fruit taste with a light kelp aftertaste. Recipe 2 demonstrated the best organoleptic characteristics due to its rich berry flavor and aroma, slightly accented by kelp, compared to other formulations (Table 4).

Table 4

Organoleptic quality indicators of pastila with seaweed

|

Recipe |

Color |

Taste |

Aroma |

Texture |

|

1 |

Dark orange |

Moderately sweet with dried apricot flavor |

Dried fruit aroma |

Jelly-like, moderately firm |

|

2 |

Dark burgundy |

Sweet, berry-like |

Bright berry aroma |

|

|

3 |

Yellowish green |

Sweet with pronounced kelp aftertaste |

Dried fruit aroma |

Firm, jelly-like |

|

4 |

Brown with dark green inclusions |

Sweet with light kelp and carrot aftertaste |

Mild berry aroma |

Jelly-like, firm |

|

5 |

Burgundy |

Sweet with slight tartness |

Berry aroma |

Jelly-like, moderately firm |

The pastila was packaged in polymer bags and stored at 18 °C and 75-80% relative humidity for 6 months. Microbiological monitoring was conducted monthly. During the entire shelf life, the total microbial count (QMAFAnM) remained within acceptable limits (not exceeding 1.0 × 10³ CFU/g), ranging from 2.5 × 10¹ to 1.8 × 10² CFU/g. Tests for coliform bacteria (BGKP), yeast, and mold were negative (Table 5).

Table 5

Microbiological indicators of pastila with seaweed

|

Indicator |

Acceptable limit |

Measured values |

|

Total mesophilic aerobic and facultative-anaerobic |

≤ 1 × 10³ |

2.5 × 10¹ to 1.8 × 10² |

|

Coliform bacteria (BGKP), per 0.1 g |

Not allowed |

Not detected |

|

Mold, CFU/g |

≤ 100 |

|

|

Yeast, CFU/g |

≤ 50 |

The results of the organoleptic properties of the pastila with seaweed showed that immediately after preparation it had a jelly-like, dense to moderately dense consistency. The color of the pastila varied from dark orange to brown with a greenish tint. The products had a pleasant smell of dried fruits or berries, with the aroma of the added components and a pleasant sweet taste, with a slight flavor of kelp and other added components. The pastila prepared according to recipe 2 received the highest score. Of the developed pastila recipes, after conducting a point assessment of the organoleptic quality indicators, it is possible

to conduct a prolongation in descending order: recipe 2, 4, 5, 1, 3.

|

a |

b |

|

c

|

d

|

|

e

|

|

Fig. 2. Profilograms of changes in organoleptic quality indicators

of pastilles with seaweed depending on the shelf life:

a – recipe 1; b – recipe 2; c – recipe 3; d – recipe 4; e – recipe 5

After 3 months of storage, a slight intensification of kelp aroma was observed in Recipes 1, 4, and 5. In Recipe 3, more significant changes were noted – darkening of the surface and increased sweetness. After

6 months, some samples developed a stronger sweet taste and a diminished aroma, but overall organoleptic properties remained satisfactory.

Toxicological testing confirmed that all contaminant levels remained within permissible limits throughout the shelf life

Table 6

Safety indicators of pastila with seaweed, mg/kg

|

Indicator |

Permissible limit |

Measured value |

|

Toxic elements |

||

|

Lead Arsenic Cadmium Mercury |

≤ 1.0 |

0.16 ± 0.05 |

|

≤ 1.0 |

0.014 ± 0.01 |

|

|

≤ 0.1 |

Not detected |

|

|

≤ 0.01 |

||

|

Pesticides |

||

|

Hexachlorocyclohexane (α, β, γ isomers) |

≤ 0.2 |

Not detected |

|

DDT and metabolites |

≤ 0.4 |

|

|

Mycotoxins |

||

|

Aflatoxin B |

≤ 0.005 |

Not detected |

The shelf life of pastila packaged in polymer bags has been established: at a temperature of 18 ℃ and humidity of 75-80% – 6 months.

Conclusions

Thus, formulations of pastila incorporating seaweed, vegetables, fruits, and berries have been developed. A stepwise drying regime was applied: Phase 1 – 46 °C for 5 hours; Phase 2 – 58 °C or 5 hours; Phase

3 – 35 °C for 3 hours. The shelf life of pastila in polymer packaging was determined to be 6 months under storage conditions of 18 °C and 75-80% relative humidity. Organoleptic characteristics, nutritional and energy values, and safety indicators were assessed. The results confirm that the quality of the product complies with the requirements established by the current technical regulations for this type of confectionery.

1. Lovkis Z., Morgunova E. Funktsional'nye produkty pitaniia [Functional food products]. Nauka i innovatsii, 2019, no. 12 (202), pp. 13-17.

2. Aslonova M. A., Derevitskaia O. K., Dydykin A. S. Funktsional'nye miasnye produkty: problemy i perspektivy [Functional meat products: problems and prospects]. Mi-asnaia industriia, 2018, no. 3, pp. 38-42.

3. Doronin A. F. Funktsional'nye pishchevye produkty [Functional food products]. Moscow, Deli print Publ., 2009. 286 p.

4. Vafina L. Kh., Podkorytova A. V. Novye produkty funktsional'nogo pitaniia na osnove bioaktivnykh kompo-nentov burykh vodoroslei [New functional nutrition products based on bioactive components of brown algae]. Izvestiia TINRO, 2009, vol. 156, pp. 348-356.

5. Berketova L. V., Gribova N. A. Izuchenie i vliianie rastitel'nykh polisakharidov dlia fruktovykh konditerskikh izdelii na osnove vtorichnykh resursov konservnogo proizvodstva [Study and effect of plant polysaccharides for fruit confectionery products based on secondary canning resources]. Vestnik Voronezhskogo gosudarstvennogo universiteta inzhenernykh tekhnologii, 2020, vol. 82 (4), pp. 147-151.

6. Dombrovskaia Ia. P., Derkanosova A. A., Belokurova E. V., Kurchaeva E. E., Maksimov I. V., Kashirina N. A. Nauchno-prakticheskie podkhody k razrabotke konditerskikh izdelii novogo pokoleniia [Scientific and practical approaches to the development of new generation confectionery products]. Vestnik Voronezhskogo gosudarstvennogo universiteta inzhenernykh tekhnologii, 2020, no. 82 (4), pp. 60-68.

7. Kabirov R. R., Gaisina L. A., Sukhanova N. V., Krasnova V. V. Biotekhnologicheskie aspekty ispol'zovaniia mik-roskopicheskikh vodoroslei i tsianobakterii [Biotechnological aspects of the use of microscopic algae and cyanobacteria]. Mezhdunarodnyi zhurnal eksperimental'nogo obrazovaniia, 2016, no. 7, pp. 128-129.

8. Al'shevskaia M. N., Trofimova V. Iu. Nauchnoe obosnovanie sovershenstvovaniia tekhnologicheskikh parametrov beskleevoi pastily [Scientific substantiation of improvement of technological parameters of glue-free paste]. Vestnik KamchatGTU, 2018, no. 46, pp. 15-22.

9. Ivanova P. Kh., Mikhova T. M. Razrabotka inno-vatsionnogo vysokokontsentrirovannogo produkta «Pastila iz sinikh sortov slivy domashnei i oblepikhi» [Development of an innovative highly concentrated product “Pastille from blue varieties of domestic plum and sea buckthorn”]. Mediko-biologicheskie problemy zdorov'ia cheloveka, 2019, no. 14, pp. 204-211.

10. Petrukhin D. A., Kovaleva E. D., Kliuchko N. Iu. Sovremennye tendentsii v proizvodstve marmelado-pastil'nykh izdelii [Current trends in the production of marmalade and pastille products]. Vestnik molodezhnoi nauki, 2020, no. 3 (25), pp. 1-8.