Russian Federation

Russian Federation

Russian Federation

Russian Federation

The article presents the results of a research of the modes of heat treatment of molded pollock products imitating pasta ones. Molded products imitating pasta ones made from pollock in the shape of noodles 2-4 mm thick, with a ribbon width of 3-6 mm, and a length of at least 15 cm, have been considered as the object of the research. To determine the organoleptic parameters, a descriptive method, a method using point scales, and a method based on the use of profilograms have been used. The results of experiments to determine the optimal modes of heat treatment are presented. The molded samples have been brought to culinary readiness by three types of heat treatment: cooking in boiling water, deep-frying with a frying fat temperature of 140-170 °C, and hot steam treatment with a temperature of 96-98 °C. At the end of the heat treatment, the samples were predried with hot air at a temperature of 60-70 °C; the temperature range was selected taking into account the maximum drying speed, provided that the deformation of the products was minimal. When using hot steam treatment, the test samples were also predried with hot air at a temperature of 40 °C. As a result of the research conducted, the methods of processing by boiling in water and deep-frying were found to be unsatisfactory. The results obtained indicate that it is advisable to use steam heat treatment of molded pollock products imitating pasta ones. The best organoleptic characteristics were obtained with the following treatment modes: steam treatment in 3 stages: 1) preliminary predrying with hot air at 40 °C for 10 minutes, 2) hot steam treatment at 96-98 °C for 10 minutes, 3) predrying with hot air at 60-70 °C for 15 minutes.

pollock, molded fish products, descriptor profile method, organoleptic parameters, heat treatment solutions

Introduction

Fishing is the key industry in the Russian Far East. The Far Eastern Federal District makes an overwhelming contribution to the yield of aquatic biological resources (73% of the total yield in the Russian Federation). Russian fishermen have been setting the highest records for pollock fishing for several years now, e.g. in 2024, pollock catch increased by 2% compared to the previous year and amounted to a record 1.99 million tons, reaching almost 41% of the All-Russian catch, identifying pollock as the main commercial resource [1-3]. In 2023, only 32% of pollack catches were used for the production of deep-processed products – fillets, minced meat, surimi, having decreased by 13% compared to the previous year. In 2024, the situation improved: the production of pollock fillets increased 2.6 times over the year, exceeding 46 thousand tons; supplies of pollock surimi increased 1.9 times, to 21 thousand tons; for minced meat, the growth compared to 2023 was 73%, up to 8 thousand tons [4-8].

It is known that seafood consumption in the Russian Federation lags significantly behind developed industrial countries. The existing shortage of full-value protein in the diet of the population increases the demand for animal products, especially for fish [9, 10]. The demand of modern consumers is for fully ready-for-use products, the preparation of which does not take any time.

In connection with the above, an important task is to expand the range of fish products, in particular, of pollock, to create new products that are in popular demand due to the simplicity of preparation, attractive organoleptic characteristics, high biological value and an adequate price. To solve this problem, the development of an economically valid method for the production of molded fish products from minced pollock, imitating the outward appearance of pasta. Such a product will have a familiar appearance; meanwhile fully ready-for-use products are expected to be developed. In connection with the above, the development of the technology for molded products made from minced pollock, imitating pasta, is considered to be an urgent area of research.

Rational technological modes of heat treatment of molded pollock products imitating pasta ones, are substantiated.

The aim of the work at this stage is to substantiate the modes of heat treatment of molded pollock products imitating pasta ones.

To achieve this aim, the task has been to determine the optimal conditions for heat treatment of molded pollock products imitating pasta ones.

Materials and methods

Molded products imitating pasta ones made from pollock noodles 2-4 mm thick, with a ribbon width of 3-6 mm, and a length of at least 15 cm have been considered as the object of the research. Experimental studies have been conducted in the laboratories of the Kamchatka State Technical University.

To determine the organoleptic parameters, a descriptive method, a method using point scales, and a method based on the use of profilograms, have been used. When selecting samples to determine organoleptic parameters and the quality of finished products, the instructions of Federal standard 31339-2006 “Fish, non-fish objects and products from them. Acceptance rules and sampling methods” [11], Federal standard 7631-2008 “Fish, non-fish objects and products from them. Methods of determining organoleptic and physical parameters”, have been followed [12].

Statistical processing of the obtained experimental data has been carried out by calculating the averages of the values and the standard average error, as well as graphoanalytically. The data have been systematized and summarized using the Astra Linux operating system program. The numerical values given are an arithmetic mean with a confidence interval of ±10% and a confidence probability of P = 0.95, to ensure the reliability of the results.

Results and discussion

When conducting research to substantiate the modes of heat treatment of molded products, an important quality criterion was the organoleptic assessment. Organoleptic tests are of the greatest importance in developing new types of food products. The quantitative descriptor-profile method proposed by the company Tragon (USA) in the 70s of the twentieth century allows for a comprehensive comparative assessment

of quality in the process of developing new types of products by quantifying the most significant organoleptic properties of food products and by using

a set of scales [13, 14].

At the previous stage of research, a recipe of molded products made from minced pollock, imitating pasta ones, was developed. Milk whey was used primarily as a corrector of the organoleptic parameters of the product, as well as a source of biologically valuable nutrients.

One of the main operations of producing molded pollock products imitating pasta ones is heat treatment, the purpose of which is to bring the products to culinary readiness. Experiments have been conducted to determine the optimal modes of heat treatment of molded pollock products imitating pasta ones.

To conduct the research, samples of products prepared according to the recipe shown in Table 1 have been formed.

Table 1

Recipe of molded products from minced walleye pollock, imitating pasta ones, with the addition of milk whey

|

Consumption of raw material per 100 g of finished minced mixture, g |

||||||||

|

Minced pollock* |

Drinking water |

Potato starch |

Tapioca starch |

Hen’s egg |

White salt, alimentary |

Sodium alginate |

Citric acid, alimentary |

Powdered milk whey |

|

51.5 |

6.0 |

15.0 |

5.0 |

15.4 |

0.5 |

0.5 |

0.1 |

6.0 |

* Minced walleye pollack was pre-aged in milk whey in a 1 : 1 ratio of whey : ground walleye pollock, followed by pressing to a minced meat moisture content of 51% (±5).

The molded samples were brought to culinary readiness by three types of heat treatment: cooking in boiling water, deep-frying with a frying fat temperature of 140-170 °C, and hot steam treatment with a temperature of 96-98 °C. At the end of the heat treatment, the samples were dried with hot air at a temperature of 60-70 °C; the temperature range was selected taking into account the maximum drying speed, provided that the deformation of the products was minimal. When using hot steam treatment, the test samples were also pre-dried with hot air at a temperature of 40 °C in order to stabilize the shape – preliminary experiments showed that in the absence of pre-drying with this type of heat treatment, the molded products stick together. It is also considered inexpedient to use hotter air for pre-drying, which leads to the deformation of raw products’ shape, while reducing the air temperature during pre-drying below 40 °C did not allow to stabilize the shape of the products. The plan of the experiment is presented in Table 2.

Table 2

Values of variable factors, their intervals and limits of variation

|

Type of heat treatment |

Dimension |

Levels |

Variation intervals |

||

|

–1 |

0 |

+1 |

|||

|

Cooking in boiling water |

min |

5 |

10 |

15 |

5 |

|

Deep-frying |

1 |

3 |

5 |

2 |

|

|

Hot steam treatment |

5 |

10 |

15 |

5 |

|

|

Hot air drying after heat treatment |

5 |

10 |

15 |

5 |

|

To determine the organoleptic parameters of the final product, organoleptic evaluation scales were deve-

loped; they are presented in Tables 3, 4.

Table 3

Scale of organoleptic evaluation of molded products imitating pasta ones

(types of heat treatment: cooking in boiling water, hot steam treatment)

|

Indicator |

Point estimation |

Characteristic |

Weight factor |

|

Color |

5 |

One-color, white/light yellow, corresponding to the raw materials used |

0.25 |

|

4 |

One-color, slightly darker or lighter |

||

|

3 |

Significantly darker or lighter |

||

|

2 |

Not one-color |

||

|

1 |

Grey |

||

|

Smell |

5 |

Pleasant, distinct, milky, characteristic of this product, without secondary odor |

|

|

4 |

Milky, characteristic of this product, without secondary smell, but not distinct enough |

||

|

3 |

Faintly distinct, characteristic of this product, without secondary odor |

||

|

2 |

Indistinct, “empty”, light fishy smell fishy smell |

||

|

1 |

Secondary, distinct fishy smell |

||

|

Taste |

5 |

Milky, quite distinct, characteristic of this product, without secondary after-taste |

1.0 |

|

4 |

Milky, characteristic of this product, without secondary after-taste, not distinct enough |

||

|

3 |

Milky, characteristic of this product, without secondary after-taste, faintly distinct |

||

|

2 |

Non-distinct, secondary tastes are present |

||

|

1 |

Secondary / fishy, raw, not typical for this product |

||

|

Consistence |

5 |

Resilient |

0.5 |

|

4 |

Softened |

||

|

3 |

Soft/dense |

||

|

2 |

Soft, slightly spreading / rather rigid |

||

|

1 |

Strongly spreading / rigid |

||

|

Surface condition |

5 |

Surface is smooth |

0.25 |

|

4 |

Surface is smooth, some products have a rough surface |

||

|

3 |

Surface is rough |

||

|

2 |

Some of the products have cracks |

||

|

1 |

A significant number of products have cracks |

||

|

Shape |

5 |

The shape is correct, corresponding to the type of the products (noodles) |

0.5 |

|

4 |

The shape is correct, corresponding to the type of the products (noodles), |

||

|

3 |

Most of the products have a correct shape corresponding to the type of products (noodles), a small part of them loses shape, the products stick slightly together |

||

|

2 |

Products partially lose their shape and noticeably stick together |

||

|

1 |

A significant number of products lose their shape and stick noticeably together |

Table 4

Scale of organoleptic evaluation of molded products imitating pasta ones (type of heat treatment – deep-frying)

|

Indicator |

Point estimation |

Characteristic |

Weight factor |

|

Color |

5 |

One-color, golden, corresponding to the raw materials used |

0.25 |

|

4 |

One-color, slightly darker or lighter |

||

|

3 |

Considerably darker or lighter |

||

|

2 |

Not one-color |

||

|

1 |

Grey, dark yellow, brown, dark-colored products |

||

|

Smell |

5 |

Pleasant, distinct, milky, characteristic of this product, with no secondary odor |

|

|

4 |

Milky, characteristic of this product, with no secondary odor, but not distinct enough |

||

|

3 |

Faintly distinct, characteristic of this product, with no secondary odor |

||

|

2 |

Not distinct, “empty”, slight fishy smell, burnt |

||

|

1 |

Secondary, distinct, fishy smell, burnt |

||

|

Taste |

5 |

Milky, quite distinct, characteristic of this product, with no secondary after-taste |

1.0 |

|

4 |

Milky, characteristic of this product, with no secondary after-taste, insufficiently distinct |

||

|

3 |

Milky, characteristic of this product, with no secondary after-taste, faintly distinct |

||

|

2 |

Not distinct, secondary after-tastes are present |

||

|

1 |

Secondary / fishy, raw, not characteristic of this product, bitter |

||

|

Consistence |

5 |

Resilient |

0.5 |

|

4 |

Softened |

||

|

3 |

Soft/dense |

||

|

2 |

Soft, slightly spreading / rather rigid, crumbling |

||

|

1 |

Strongly spreading / rigid, moist / dry |

||

|

Surface condition |

5 |

Surface is smooth |

0.25 |

|

4 |

Surface is smooth, some products have a rough surface |

||

|

3 |

Surface is rough |

||

|

2 |

Some of the products have cracks |

||

|

1 |

A significant number of products have cracks |

||

|

Shape |

5 |

The shape is correct, corresponding to the type of the products (noodles) |

0.5 |

|

4 |

The shape is correct, corresponding to the type of the products (noodles), the edges are slightly distended |

||

|

3 |

Most of the products have a correct shape corresponding to the type of products (noodles), a small part of them loses shape, the products stick slightly together, partially burnt |

||

|

2 |

Products partially lose their shape and noticeably stick together, a significant part is burnt |

||

|

1 |

A significant number of products lose their shape, get deformed, stick noticeably together, are burnt |

The modes of heat treatment of the samples under study by cooking in boiling water are shown in Table 5.

Table 5

Modes of heat treatment of the studied samples by cooking in boiling water,

followed by predrying with hot air at a temperature of 60-70 °C

|

Types of heat treatment |

Heat treatment modes of samples, min |

||||||||

|

1.1 |

1.2 |

1.3 |

2.1 |

2.2 |

2.3 |

3.1 |

3.2 |

3.3 |

|

|

Cooking in boiling water |

5 |

10 |

15 |

||||||

|

Predrying with hot air |

5 |

10 |

15 |

5 |

10 |

15 |

5 |

10 |

15 |

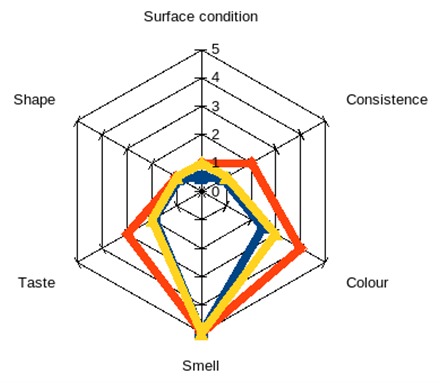

The organoleptic evaluation of the samples was carried

out using a profile method; the results are shown in Fig. 1.

a b

c

Fig. 1. Profilograms of organoleptic parameters of molded products imitating pasta ones;

heat treatment – cooking in boiling water followed by predrying with hot air at a temperature of 60-70 °C:

a – cooking time of 5 min (samples 1.1, 1.2. 1.3); b – cooking time of 10 min (samples 2.1, 2.2. 2.3);

c – cooking time 15 min (samples 3.1, 3.2. 3.3)

Samples No. 1.1-1.3, 2.1-2.3, 3.1-3.3, after molding, were subjected to cooking for 5, 10, and 15 minutes, respectively, followed by predrying. All products received a negative rating – the finished product boiled soft and partially dissolved in water during cooking, and the yield of finished products was minimal. As a result of the research conducted, the method of processing by cooking in water was found unsatisfactory.

The modes of heat treatment of the samples under study by deep frying are shown in Table 6.

Table 6

Modes of heat treatment of the studied samples by deep frying, the temperature of the frying fat is 140-170 °C,

followed by predrying with hot air at a temperature of 60-70 °C

|

Types of heat treatment |

Heat treatment modes of samples, min |

||||||||

|

4.1 |

4.2 |

4.3 |

5.1 |

5.2 |

5.3 |

6.1 |

6.2 |

6.3 |

|

|

Deep frying |

1 |

3 |

5 |

||||||

|

Predrying with hot air |

5 |

10 |

15 |

5 |

10 |

15 |

5 |

10 |

15 |

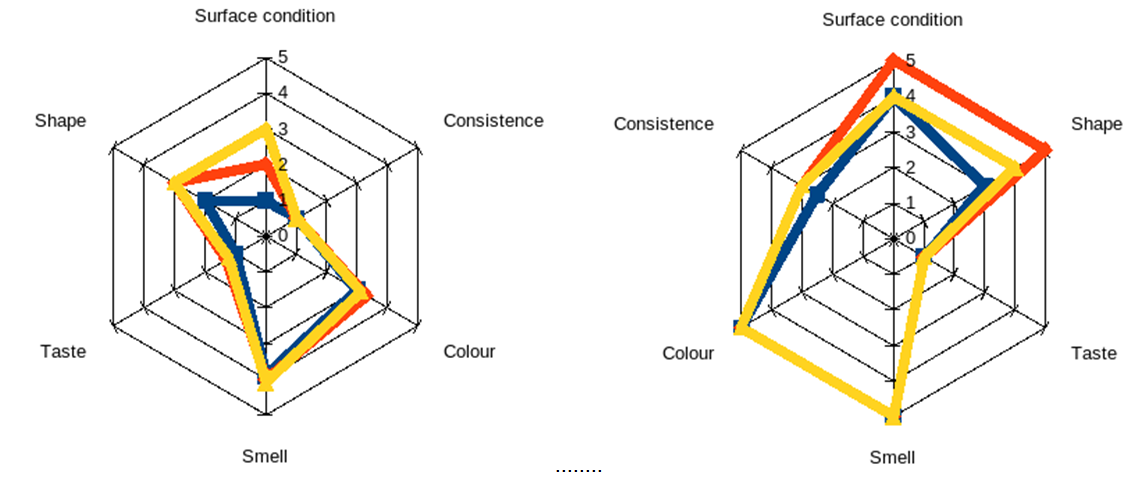

The organoleptic evaluation of the samples was carried out using a profile method; the results are shown in Fig. 2.

c

Fig. 2. Profilograms of organoleptic parameters of molded products imitating pasta ones;

heat treatment – deep frying followed by predrying with hot air at a temperature of 60-70 °C:

a – roasting time 1 min (samples 4.1, 4.2. 4.3); b – roasting time 3 min (samples 5.1, 5.2. 5.3);

c – roasting time is 5 min (samples 6.1, 6.2. 6.3)

Samples No. 4.1-4.3, 5.1-5.3, 6.1-6.3 after molding, they were deep-fried and then dried. Samples No. 4.1-4.3, 6.1-6.3 – the result is unsatisfactory. Samples No. 4.1-4.3 have a crude consistency; samples No. 6.1-6.3 have acquired a dark yellow unattractive color. Samples No. 5.1-5.3 received a positive assessment in terms of shape, surface condition, smell, and color. The resulting product is a noodle-shaped product, golden yellow in color. At the same time, it was found that the inside of the products was not brought to culinary readiness, and the taste was raw.

The modes of heat treatment of the samples under study by with hot steam are shown in Table 7.

Table 7

Modes of heat treatment of the studied samples with hot steam at a temperature of 96-98 °C,

with preliminary predrying with hot air at a temperature of 40 °C for 10 minutes

and subsequent predrying with hot air at a temperature of 60-70 °C

|

Types |

Heat treatment modes of samples, min |

||||||||

|

7.1 |

7.2 |

7.3 |

8.1 |

8.2 |

8.3 |

9.1 |

9.2 |

9.3 |

|

|

Preliminary predrying with hot air, temperature |

10 |

||||||||

|

Treatment with hot steam, temperature |

5 |

10 |

15 |

||||||

|

Predrying with hot air, temperature |

5 |

10 |

15 |

5 |

10 |

15 |

5 |

10 |

15 |

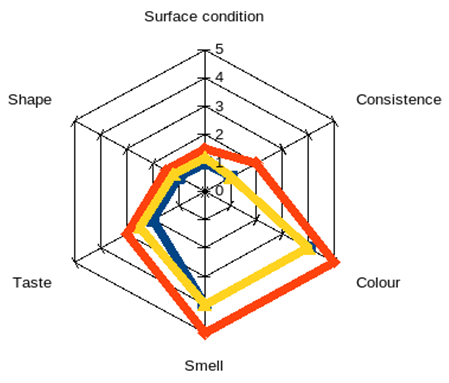

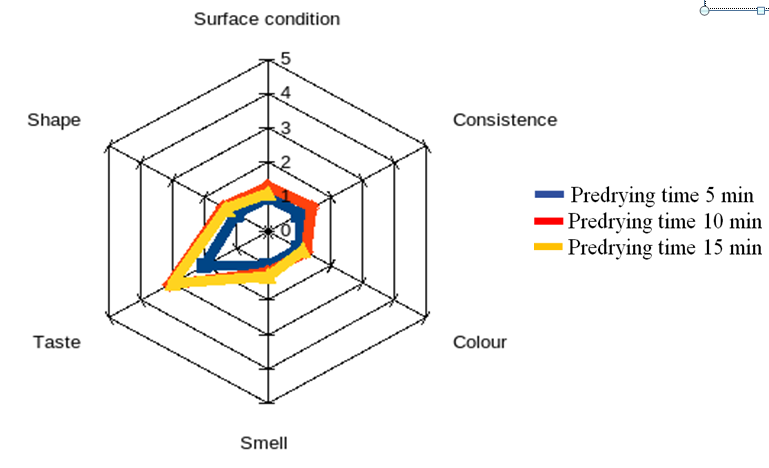

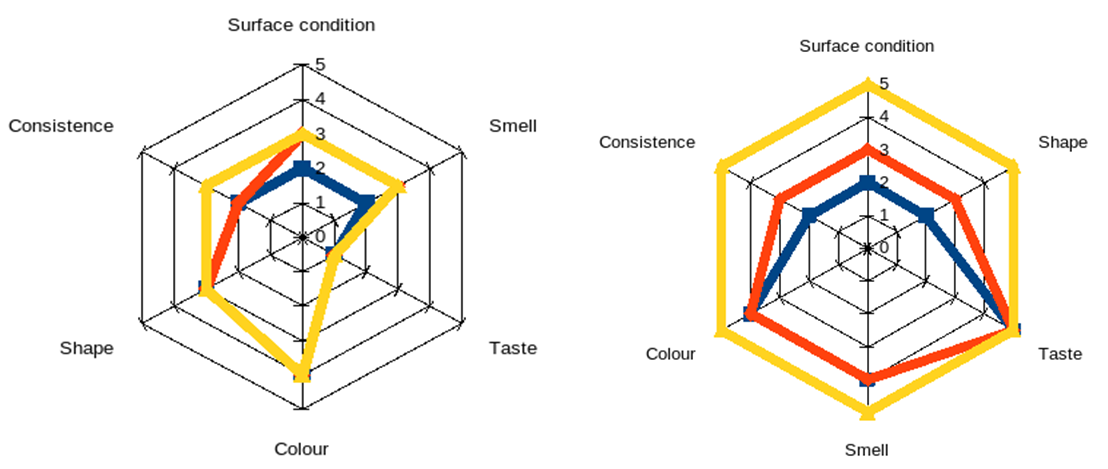

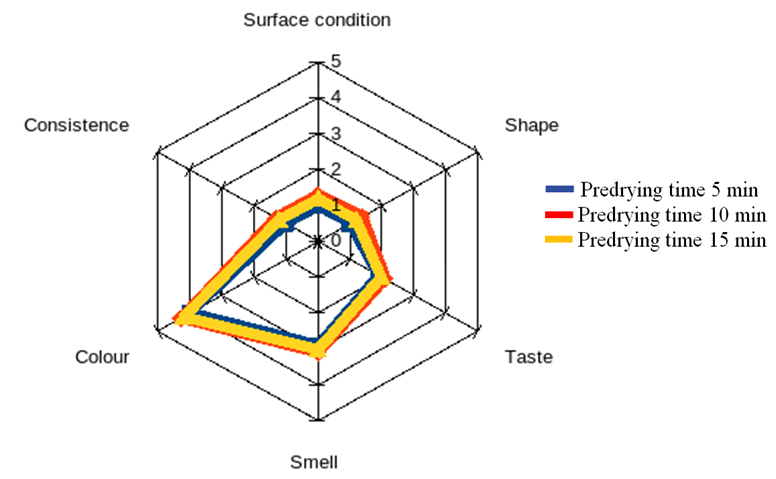

The organoleptic evaluation of the samples was carried out using a profile method; the results are shown in Fig. 3.

a b

c

Fig. 3. Profilograms of organoleptic parameters of molded products imitating pasta ones;

heat treatment – with hot steam at a temperature of 96-98 °C, with preliminary predrying with hot air

at a temperature of 40 °C for 10 min and subsequent predrying with hot air at a temperature of 60-70 °C:

a – time of heat treatment 5 min (samples 7.1, 7.2. 7.3); b – the time of heat treatment is 10 min (samples 8.1, 8.2. 8.3);

c – the time of heat treatment is 15 min (samples 9.1, 9.2. 9.3)

Samples No. 7.1-7.3, 8.1-8.3, 9.1-9.3, after molding, were subjected to preliminary predrying for 10 minutes with hot air at a temperature of 40 °C to preserve the shape, then treated with hot steam for 5, 10, 15 mi-

nutes, respectively, followed by predrying. The products subjected to steam treatment for 5 minutes (samples No. 7.1-7.3.) remained raw, and within 15 minutes (samples No. 9.1-9.3) lost their shape and boiled soft. The best result was obtained by steaming the products for 10 minutes, followed by predrying for 15 minutes (sample No. 9.3). After heat treatment and cooling, the finished product acquired a familiar shape similar to traditional noodles. The study of the organoleptic parameters of sample No. 9.3 showed that the resulting product is a noodle-shaped product, light yellow in color with a grayish tinge and an easily chewable consistency. The taste and aroma are characteristic of this product with a subtle milky aroma and a pleasant milky aftertaste; the products do not stick together after cooking; there is no deformation; the shape of the noodles is preserved.

Conclusion

The results obtained indicate that it is advisable to use steam heat treatment of molded pollock products imitating pasta ones. The best organoleptic parameters have been obtained under the following treatment modes:

– steam treatment in 3 stages: 1) preliminary predrying with hot air at 40 °C for 10 minutes; 2) hot steam treatment at 96-98 °C for 10 minutes; 3) predrying with hot air at 60-70 °C for 15 minutes.

The practical use of the results obtained lies in the fact that the developed processing modes will allow the production of a new type of pollock products – molded products imitating pasta ones, which will facilitate the sale of pollock by fish processing enterprises of the Russian Federation, and will also allow more active introduction of pollock products into the diet of the Russian population, which are currently not in high demand. In further research, it is planned to rely on well-founded heat treatment parameters.

1. Rossiia pribavila v glubokoi pererabotke mintaia [Russia has added to the deep processing of pollock]. Available at: https://fishnews.ru/news/52016 (accessed: 23.01.2025).

2. Semin A. N., Truba A. S. Rossiiskii rynok mintaia: sovremennoe sostoianie i puti ego razvitiia [The Russian pollock market: current state and ways of its development]. Trudy VNIRO, 2023, vol. 193, pp. 216-221.

3. Ulov mintaia v Rossii po itogam 2024 goda okazalsia pochti napolovinu bol'she, chem v SShA [The pollock catch in Russia by the end of 2024 turned out to be almost half as much as in the United States]. Available at: https://pollock.ru/news/ulov-mintaya-v-rossii-po-itogam-2024-goda-okazalsya-pochti-napolovinu-bolshe-chem-v-ssha/ (accessed: 18.03.2025).

4. Bulatov O. A. K voprosu o metodologii prognoziro-vaniia zapasov i strategii promysla mintaia [On the method-ology of forecasting stocks and the strategy of pollock fishing]. Trudy VNIRO, 2022, vol. 157, pp. 45-70.

5. Varkentin A. I., Sergeeva N. P. Promysel mintaia (Theragra chalcogramma) v prikamchatskikh vodakh v 2003–2015 gg. [Pollock fishing (Theragra chalcogramma) in the Kamchatka waters in 2003-2015]. Issledovaniia vodnykh biologicheskikh resursov Kamchatki i severo-zapadnoi chasti Tikhogo okeana, 2017, iss. 47, pp. 5-45.

6. Efimova M. V., Efimov A. A., Mustafaeva V. M., Chmykhalov B. A. Mintai tikhookeanskii – perspektivnyi syr'evoi ob"ekt rybnoi otrasli Rossii [Pacific pollock is a promising raw material object of the Russian fishing indus-try]. Vestnik KamchatGTU, 2022, no. 62, pp. 18-35.

7. Kolonchin K. V., Pavlova A. O., Betin O. I., Ianovskaia N. V. Mintai kak ob"ekt rossiiskogo i mirovogo promysla [Pollock as an object of Russian and world fish-ing]. Trudy VNIRO, 2022, vol. 189, pp. 5-15.

8. Chupikova E. S., Saiapina T. A., Bashtovoi A. N.,Iakush E. V. Nekotorye aspekty tekhnologii rybnogo farsha “Surimi” pri glubokoi pererabotke mintaia [Some aspects of the technology of minced fish “Surimi” in the deep processing of pollock]. Rybnoe khoziaistvo, 2023, no. 3, pp. 109-115.

9. Ryzhkova S. M., Kruchinina V. M. Tendentsii potre-bleniia ryby i produktov ee pererabotki v Rossii [Trends in consumption of fish and processed products in Russia]. Vestnik VGUIT, 2020, no. 2 (84), pp. 181-189.

10. Gorbatovskiy A. A., Rakityanskaya I. L., Kaledina M. V. Minced products from undersized sea fish: new industrial technology. Foods and Raw Materials, 2021, no. 9 (1),pp. 87-94.

11. GOST 31339-2006. Ryba, nerybnye ob"ekty i produktsiia iz nikh. Pravila priemki i metody otbora prob [ISS 31339-2006. Fish, non-volatile objects and products from them. Acceptance rules and sampling methods]. Moscow, Standartinform Publ., 2010. 18 p.

12. GOST 7631-2008. Ryba, nerybnye ob"ekty i produktsiia iz nikh. Metody opredeleniia organolepticheskikh i fizicheskikh pokazatelei [ISS 7631-2008. Fish, non-volatile objects and products from them. Methods for determining or-ganoleptic and physical parameters]. Moscow, Standartinform Publ., 2011. 15 p.

13. Kantere V. M., Matison V. A., Fomenko M. A. Sensornyi analiz produktov pitaniia: monografiia [Sensory analysis of food products: monograph]. Moscow, Tipografiia RASKhN, 2003. 400 p.

14. Matison V. A., Arutiunova N. I., Goriacheva E. D. Primenenie deskriptorno-profil'nogo metoda dlia otsenki kachestva produktov pitaniia [Application of the descriptor-profile method for food quality assessment]. Pishchevaia promyshlennost', 2015, no. 6, pp. 52-54.